“We have been using the Hallmark Group as our sole supplier of Aluminium panels since we formed in 2011. We consistently receive great support from the team and look forward to continuing our relationship over the coming years.”

Laminated supplies have been market leaders for over 60 years.

Discover more about what we have to offer.

Over 60 years manufacturing and supplying heritage and expertise.

Bespoke product ranges that meet your exact specifications.

In-house reliable National delivery service.

Reduction in lead times due to in-house colour bonding.

Using our past experience and knowledge, we offer expert advice for your project or tender.

Choose from a wide range of finishes and protective coatings.

Select a product to view more details.

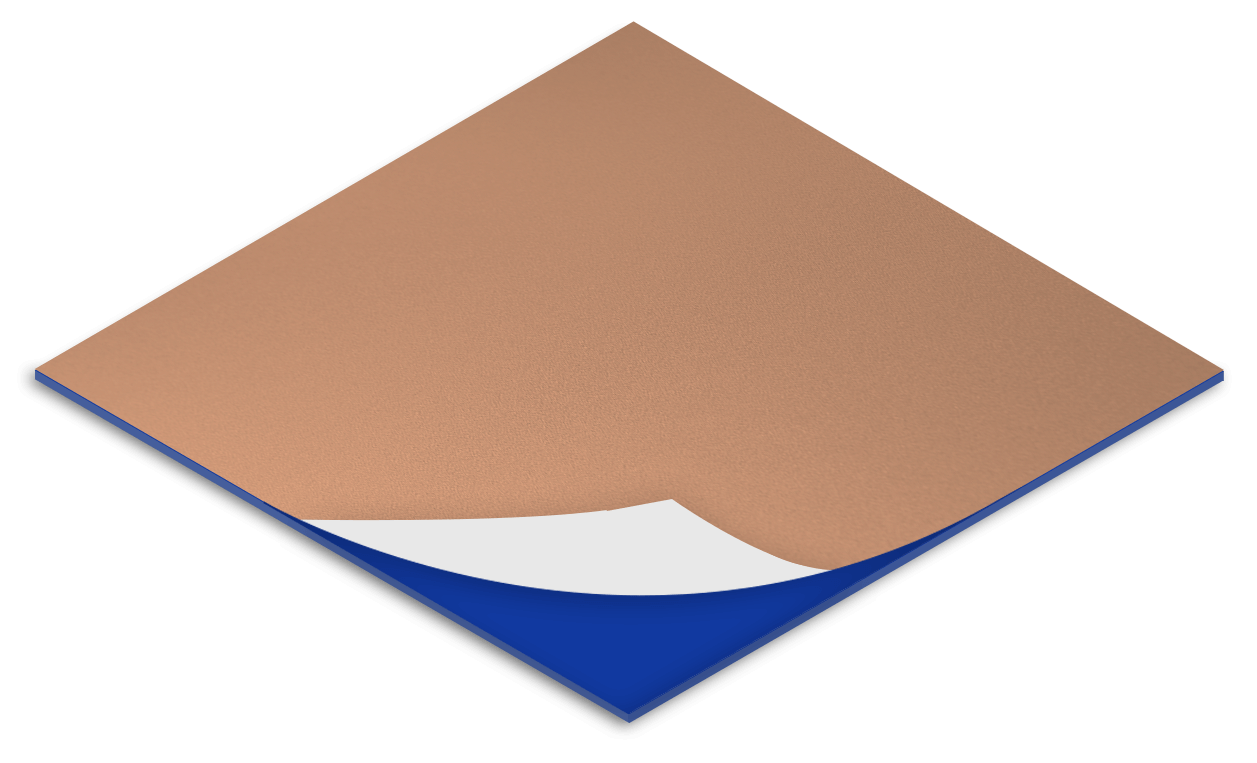

The aluminium powder coating application is a dry paint powder which is charged electrically. The aluminium sheet being coated is treated and prepared to ensure maximum lifespan of the coating. With this technique, the powder is attracted to the aluminium including a contribution of a combination of static electricity to ensure adhesion. Following the process, the aluminium is placed into an oven of subsequent high temperature to melt the polyester allowing the finish to flow and cure. At the end of this process the aluminium is cooled and is ready to be bonded.

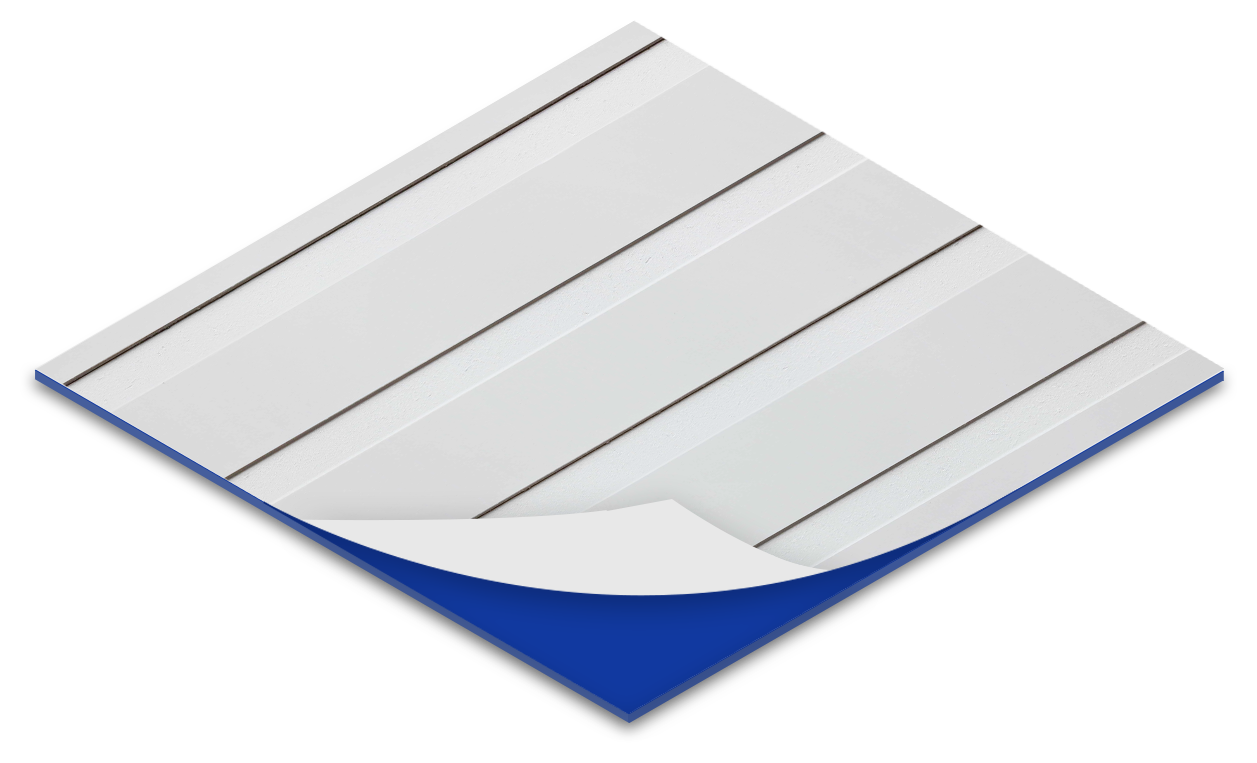

Laminated supplies offers Aluminium Shiplap panels which is exclusive to our customers. The shiplap panels are designed to simulate traditional shiplap, however exploiting the superior performance of lightweight aluminium panels.

We use a high-tech tooling to create the groove on flat sheets of aluminium to replicate the effect of timber shiplap weatherboard. This means the panels are in one piece and is easy to fit into a glazing frame.

Leading UK aluminium trade manufacturer & supplier. Our thermally efficient range of aluminium doors and aluminium panels are ideally suited to the residential, commercial & social housing markets. This collection of front doors and panels are manufactured to provide high performance solutions for today’s specification demands.

A hot dipped galvanised HDG substrate with a 200 micron coating of plastic. Plastisol infill panels are manufactured using two skins bonded to either side of an insulation material.

These panels are thermally efficient and can be manufactured to suit both existing and replacement glazing systems. The thermal efficiency of the panels can be improved by either using a better insulation material or by increasing the thickness of the insulation to achieve a specific U Value.

With its leather appearance and hard wearing qualities, it is ideal for a wide range of uses.

With over 60 years manufacturing heritage and expertise, Laminated Supplies manufacturers a comprehensive range of bespoke architectural and construction supplies to building contractors, local authorities & refurbishment industries.

Offering bespoke products allows us to manufacture bonded panels that meet customer’s unique design requirements and specifications. Our made to measure service reduces on-site labour costs by minimising fixing time, but also provides the customer with the widest possible scope in their choice of available materials.

With our heritage & expertise you can contact us to further discuss your project or tender details.

Here is a list of just some of the applications that Laminated Supplies products have been used for.

Education

Commercial

Construction

Retail

Leisure

Sport

Environment

Sign Making

Advertising

Transportation

Discover what our customers have to say...

“We have been using the Hallmark Group as our sole supplier of Aluminium panels since we formed in 2011. We consistently receive great support from the team and look forward to continuing our relationship over the coming years.”

Grieg Hayes

Complete Aluminium Systems