British Manufacturing

British ManufacturingOver 60 years' experience manufacturing & supplying construction materials.

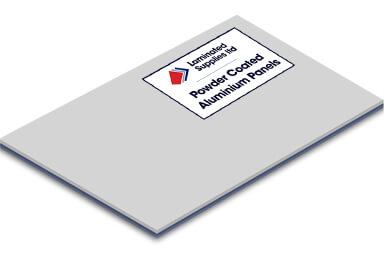

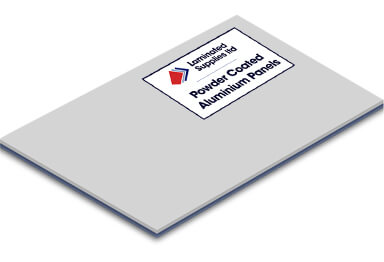

Protective Film Layer.

Powder Coated Paint Colour & Finish.

Choose from 1500+ RAL & BS colour options as well as multiple paint finishes including marine grade.

Aluminium Skin.

Choose from a range of skin thicknesses which can be cut and bent to your specifications. Typically 1.2mm - 3mm.

You can also state the thickness of the overall panel typically 24 or 28mm. (Bespoke available)

Panel Adhesive For Optimum Bonding.

Panel Core material & reinforcement options.

Choose from a number of core materials for your panels as well as optional reinforcement options.

Laminated Supplies offers a quick turnaround on powder-coated aluminium panels using our on-site powder coating plant. PPC / APC

The powder coating process involves the application of a dry paint powder which is charged electrically. The aluminium sheet being coated is treated and prepared to ensure maximum lifespan of the coating. With this technique, the powder is attracted to the aluminium including a contribution of a combination of static electricity to ensure adhesion. Following the process, the aluminium is placed into an oven of subsequent high temperature to melt the polyester allowing the finish to flow and cure. At the end of this process, the aluminium is cooled and is ready to be bonded.

This enables us to manufacture a large variety of bespoke powder coated aluminium sheets and panels.

3000 x 1250

2500 x 1250

3000 x 1500

2500 x 1000

2000 x 1000

(all sizes in mm)

1000 x 1000

2000 x 1000

3000 x 1500

(all sizes in mm)

Prices include

• 1.2mm Skin thickness

• 24mm or 28mm overall thickness

• Polystyrene core

• Standard RAL both sides - matt/satin

Cut To Size

Standard RAL Dual Colours

4mm MDF Reinforcing

We can bend our aluminium panels several times to meet exact specifications (in degrees).

Panels can be cut into bespoke shapes as well as have bespoke aperture cut into them.

Overall Thickness

Overall thickness 24mm (standard)

Overall thickness 28mm (standard)

Skin Thickness

Skin Thickness 1.2mm (standard)

Skin Thickness Range 1.2mm - 3mm

Bespoke shapes, apetures, sizes and thicknesses are available.

Bespoke RAL & BS colours available on request

Hipca White

RAL 9910

Pure White

RAL 9010

Jet Black

RAL 9005

Graphite Black

RAL 9011

Anthracite Grey

RAL 7016

Slate Grey

RAL 7015

Basalt Grey

RAL 7012

Black Grey

RAL 7021

RAL Colour

Over 100+ colours

*disclaimer - colours may vary to images shown on this website due to the nature of colour being replicated on a digital screen. We would always recommend requesting a sample before ordering.

White

Black

Anthracite

RAL 7016

Brown Red

RAL 3001

Grass Green

RAL 6010

Lemon Yellow

Red Orange

RAL 2001

Hipca White

RAL 9910

Pure White

RAL 9010

Jet Black

RAL 9005

Silver Grey

RAL 7015

Basalt Grey

RAL 7012

Black Grey

RAL 7021

Ruby Red

RAL 3003

Ochre Brown

RAL 8001

Golden Yellow

RAL 1004

Sky Blue

RAL 5015

Olive Yellow

RAL 1020

Squirrel Grey

RAL 7000

Telegrey 4

RAL 7047

Light Ivory

RAL 1015

Signal Violet

4008

RAL Colour

Over 100+ colours

*disclaimer - colours may vary to images shown on this website due to the nature of colour being replicated on a digital screen. We would always recommend requesting a sample before ordering.

Applications

Applications Powder coating finishes

Powder coating finishes Cores

Cores* Please note, these products are not fire rated.

Can be cut to bespoke shapes and can cut out bespoke apertures.

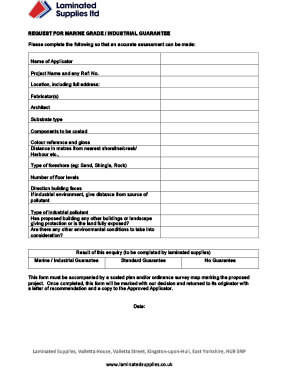

Laminated Order Form

82kb